Fire design of CLT elements. Glue line integrity maintained or not?

The check of CLT elements under fire conditions can be crucial in the design of a timber structure. Due to the layered structure of their cross-section, the calculation process is peculiar as pointed out in the examples below.

The charring depth of a CLT panel under fire conditions depends on the properties of the glue used in the panel assembly. The polyurethane glue (PUR), often used by manufacturers, is not resistant in case of high temperature meanwhile MUF glue (melamine-urea-formaldehyde) shows better performance.

This is why the new TimberTech Buildings additional module for the fire design of timber structures implements two calculation models to be applied according to the CLT properties certified by the manufacturer:

- Glue line integrity maintained: the charring rate is assumed to be constant through the whole cross-section. This method can also be used when the manufacturer’s certificates suggest a constant charring rate (higher than that of the wood) to take into account the lower performance of the glue in a simplified manner.

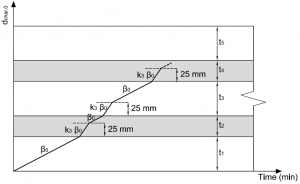

- Glue line integrity not maintained: the charring rate is not constant and depends on the panel stratigraphy. The CLT cross-section can be seen as a sequence of layers where each one acts as a protective layer for the following one. Therefore, the method for protected elements provided by EN 1995-1-2 can be applied to obtain a charring rate trend such as the one reported in the figure below where the k3 factor usually has a value of 2.

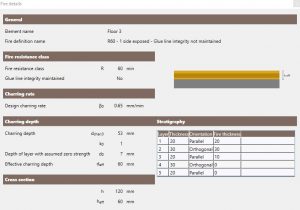

CLT design example: R60 with glue line integrity not maintained

- Cross-section: 120 mm (20-30-20-30-20)

- Glue: glue line integrity NOT maintained

- Fire exposure: 60 minutes on one side

- Unidimensional charring rate: beta0 = 0.65 mm/min

- Charring depth: dchar,0 = 53 mm. Layer 1 (constant charring rate), layer 2 (double charring rate in the first 25 mm, then constant charring rate), strato 3 (double charring rate up to the required 60′)

- Effective charring depth: def = dchar,0 + k0d0 = 60 mm

- Effective cross-section: 60 mm (20-30-10)

Bending check 101% (MEd = 11.36 kNm)

Shear check 14% (VEd = 7.81 kNm)

Download the TimberTech Buildings calculation report about this example

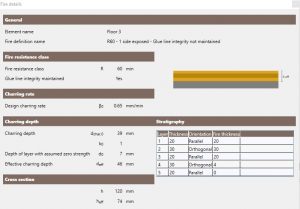

CLT design example: R60 with glue line integrity maintained

- Cross-section: 120 mm (20-30-20-30-20)

- Glue: glue line integrity NOT maintained

- Fire exposure: 60 minutes on one side

- Unidimensional charring rate: beta0 = 0.65 mm/min

- PCharring depth: dchar,0 = 39 mm. Constant charring rate through all layers

- Effective charring depth: def = dchar,0 + k0d0 = 46 mm

- Effective cross-section: 74 mm (20-30-20-4)

Bending check 55% (MEd = 11.36 kNm)

Shear check 12% (VEd = 7.81 kNm)

Download the TimberTech Buildings calculation report about this example